|

|

Post by christopher on Dec 29, 2017 15:30:54 GMT -6

When I worked doing guitar upgrades, I was surprised how lead free solder can affect tone (in a bad way). It made me think *all* the chinese stuff suffers from poor connections, of just crap conductance or something. Thanks for sharing your experience.

|

|

|

|

Post by theboris on Dec 15, 2022 10:33:06 GMT -6

I go through micro wire cutters (like Hakko CHP-170) more frequently than I like. I've tried different brands, but they always suffer the same fate: dullness and more aches in hands over long periods of time. Sharp tools are a wonderful thing. But... any advice on how to sharpen them? The problem seems getting a belt or stone in the small area between the blades, and most don't seem user-serviceable to disconnect an arm/blade.

|

|

ericn

Temp

Balance Engineer

Posts: 16,083

|

Post by ericn on Dec 27, 2022 18:04:35 GMT -6

I go through micro wire cutters (like Hakko CHP-170) more frequently than I like. I've tried different brands, but they always suffer the same fate: dullness and more aches in hands over long periods of time. Sharp tools are a wonderful thing. But... any advice on how to sharpen them? The problem seems getting a belt or stone in the small area between the blades, and most don't seem user-serviceable to disconnect an arm/blade. I gave up on the good ones and just started buying the disposable Harbor Freight copy. |

|

|

|

Post by copperx on Dec 31, 2022 1:00:14 GMT -6

How essential is an oscilloscope? I've seen some projects (AML?) require one for calibration.

Where can one find a cheap oscilloscope?

|

|

|

|

Post by stratboy on Jan 22, 2023 13:10:01 GMT -6

I go through micro wire cutters (like Hakko CHP-170) more frequently than I like. I've tried different brands, but they always suffer the same fate: dullness and more aches in hands over long periods of time. Sharp tools are a wonderful thing. But... any advice on how to sharpen them? The problem seems getting a belt or stone in the small area between the blades, and most don't seem user-serviceable to disconnect an arm/blade. You could clamp your dremel in the vise, put on a small drum or disc with the appropriate abrasive and try that. Or a set of small flat files. |

|

|

|

Post by soundtech on Mar 17, 2023 10:52:31 GMT -6

Although nothing beats a good powered vacuum de-soldering tool - my Hakko 808 changed my life - the expense can be hard to justify.

I keep one of these in my out-call kit, it works very well:

|

|

|

|

Post by audiospecific on Dec 25, 2023 6:41:02 GMT -6

So, this is what I would do now these days If I had to set up a new electronics work bench...

Hope this satisfies your tool GAS. Merry Christmas!

1. a few board vises: (PANAVISE 324 & PANAVISE Jr.)

Nice magnifying light:  Magnifying Head lamp:

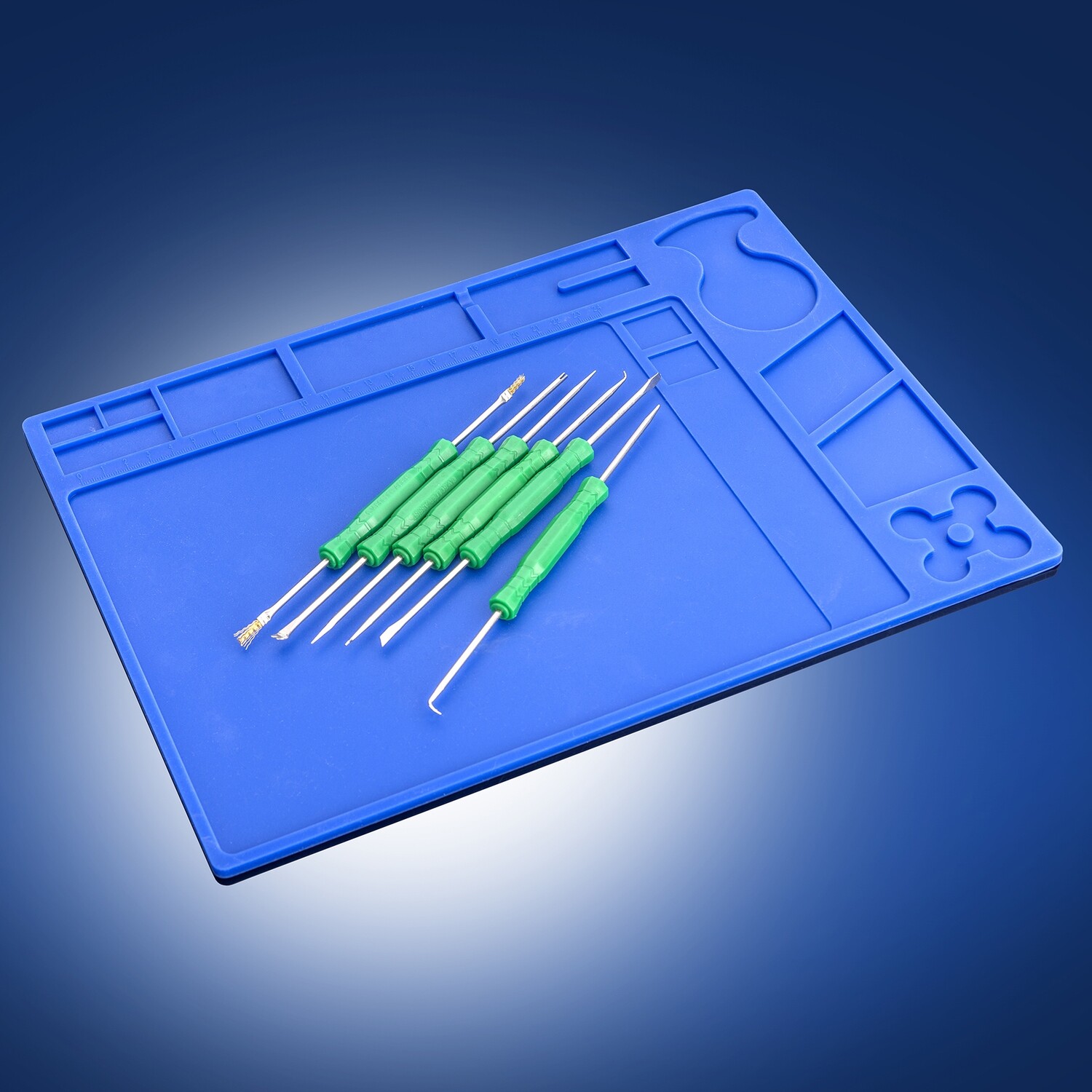

Soldering: X-Tronic 5040-XR3  X-Tronic 8020-XTS  X-Tronic Antistatic Silicone Work Mat with Included Assistive Tools - Medium  A Buck Roger's 90W vacuum desoldering station (various types, just has to be temperature controlled) B&K Precision 388B  B&K Precision TL50B Maxi-Pro DMM Kit  Siglent Technologies SDS1104X-U scope  audio function generator  BK 1604A isolation transformer and a variac

Not including other tools like needle nos, screw drivers, etc

|

|

|

|

Post by audiospecific on Dec 25, 2023 6:56:12 GMT -6

How essential is an oscilloscope? I've seen some projects (AML?) require one for calibration. Where can one find a cheap oscilloscope? I would just get a Fnirsi DSO-TC2 Handheld Digital 2-in-1 Oscilloscope Transistor Tester

this one is like $53

Like on 1081 where you set the crossover point of the amplifier (zero crossing bias) you would just need to see the waveform. You can always use computer based test signal generation like from a web site if you don't want to spend $50-$100 on an audio function generator,

Transistor checker would be useful for selecting the parts so they match specs correctly. As you select the set of transistors correctly in a matching affair.

|

|