|

|

Post by svart on Nov 25, 2014 19:28:30 GMT -6

You guys are silly muffukkas.

|

|

|

|

Post by kcatthedog on Nov 25, 2014 19:50:10 GMT -6

Zvartinator

|

|

|

|

Post by jcoutu1 on Nov 25, 2014 20:13:38 GMT -6

Are you going to use Sowter or Carnhill transformers on the input?  |

|

ericn

Temp

Balance Engineer

Posts: 16,107

|

Post by ericn on Nov 25, 2014 20:15:52 GMT -6

Idea for name

The Beast You Can Get!

|

|

|

|

Post by kcatthedog on Nov 25, 2014 20:40:58 GMT -6

Chrisasauarixrex

|

|

|

|

Post by Martin John Butler on Nov 25, 2014 22:11:37 GMT -6

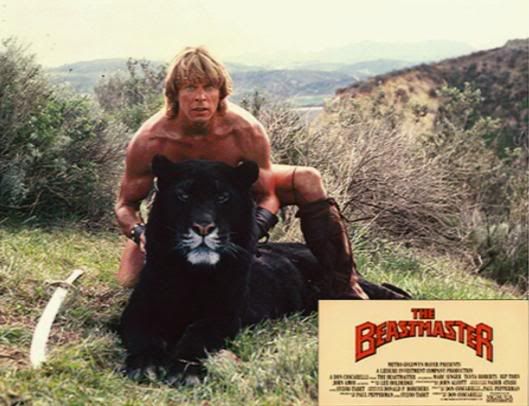

The Beastmaster !

|

|

|

|

Post by mdmitch2 on Nov 25, 2014 23:22:07 GMT -6

This made me think of the movie... which made me think of the panther in the movie, which was actually a tiger spray painted black. And since converters seem to be associated with colors, how about: Black Tiger or White Tiger  |

|

|

|

Post by mdmitch2 on Nov 25, 2014 23:24:32 GMT -6

Just occurred to me that 'Black Tiger' is surely too close to 'Black Lion'....

|

|

|

|

Post by tonycamphd on Nov 25, 2014 23:36:55 GMT -6

crouching chicken/painted tiger..... wtf? I can't believe they did that lol

|

|

|

|

Post by mdmitch2 on Nov 25, 2014 23:42:17 GMT -6

crouching chicken/painted tiger..... wtf? I can't believe they did that lol Movie animals got a bum deal in the 80's.... that's for sure. How about 'White Panther' ? Sounds like a kung fu villain. And as I look at a bottle of Cherry Coke, the name 'Cherry Smoke' comes to mind. |

|

|

|

Post by svart on Nov 26, 2014 9:19:27 GMT -6

How in the hell did they get a tiger to actually be OK with having it's fur dyed?

|

|

|

|

Post by jcoutu1 on Nov 26, 2014 9:24:02 GMT -6

It's raining dye...

|

|

|

|

Post by tonycamphd on Nov 26, 2014 13:27:56 GMT -6

|

|

|

|

Post by svart on Nov 26, 2014 16:04:51 GMT -6

So I've got the DAC board schematic mostly finished. I did a netlist and import to the PCB to gauge the density.

Whoa nelly it's going to be tight. It might be easier to route though since I've changed to mostly local voltage regulation and I can put those on the back of the PCB and do local power pours.

The PCB size and the layout of the connectors should be identical to the ADC board for the most part since I want maximum compatibility in the longrun.

I don't want to do it but I might have to go to small tantalum caps for some of the LDO outputs. I'm not sure the ceramics will keep the LDOs stable.

|

|

|

|

Post by tonycamphd on Nov 26, 2014 16:18:00 GMT -6

So I've got the DAC board schematic mostly finished. I did a netlist and import to the PCB to gauge the density. Whoa nelly it's going to be tight. It might be easier to route though since I've changed to mostly local voltage regulation and I can put those on the back of the PCB and do local power pours. The PCB size and the layout of the connectors should be identical to the ADC board for the most part since I want maximum compatibility in the longrun. I don't want to do it but I might have to go to small tantalum caps for some of the LDO outputs. I'm not sure the ceramics will keep the LDOs stable.could you elaborate on this please, i'm not sure what LDOs even means in this app(low drop out voltage?), what would be the negatives and the reason you say you don't want to use the tantalums? sorry for my ignorance. |

|

|

|

Post by svart on Nov 26, 2014 16:23:09 GMT -6

LDO is a low drop out voltage regulator. Usually a pass element and a voltage comparator in a package.

Tantalum costs a lot more than ceramic caps do, usually 3-5 times more, and can be temperamental in certain situations.

Also, the majority of the world's supply of raw tantalum comes from China who restricts the flow to keep prices high. Mining it is also dirty business and leads to a lot of polluting.

|

|

|

|

Post by svart on Nov 28, 2014 11:59:01 GMT -6

|

|

|

|

Post by svart on Nov 28, 2014 13:48:56 GMT -6

The ADC board will be here next week sometime. I suppose monday I'll order the parts for the ADC prototypes.

|

|

|

|

Post by Johnkenn on Nov 29, 2014 21:59:38 GMT -6

You know, if you made a battleship grey WWII, Abbey Road, EMI looking case, it would sell like hot cakes... |

|

|

|

Post by svart on Dec 1, 2014 10:21:29 GMT -6

Here's the populated prototype front boards.  The ADC pcbs are supposed to be here tomorrow. I just got a sample PCM4222, so I'll order the rest of the prototype parts tonight and I should be able to test power supplies and such by maybe thursday, then populating a full board maybe by the end of the week. There is tons of work to be done though, so don't take that as a sign of being close to a finished product... |

|

|

|

Post by tonycamphd on Dec 1, 2014 11:04:48 GMT -6

|

|

|

|

Post by svart on Dec 1, 2014 11:16:52 GMT -6

Well, I'm certainly not financially able to go that far in design like they are. I'm also shooting for a more narrow window of customer too. It's quite possible that they use a lot of the same design criteria on their product. The PCM4222 takes care of a number of aspects of the design for you.

However, one big difference is that they are using a OCXO (oven controlled clock oscillator) based on the "Oven" LED on the front of the unit. The oven is a heater that keeps the oscillator at a specific temperature.

I'm using a very low jitter clock device, but it's not oven controlled. OCXO's are not cheap.

|

|

|

|

Post by tonycamphd on Dec 1, 2014 11:24:38 GMT -6

Well, I'm certainly not financially able to go that far in design like they are. I'm also shooting for a more narrow window of customer too. It's quite possible that they use a lot of the same design criteria on their product. The PCM4222 takes care of a number of aspects of the design for you. However, one big difference is that they are using a OCXO (oven controlled clock oscillator) based on the "Oven" LED on the front of the unit. The oven is a heater that keeps the oscillator at a specific temperature. I'm using a very lot jitter clock device, but it's not oven controlled. OCXO's are not cheap. Understood, i was curious to what you thought about the design is all. I'd bet what ever they did still has bean counters standing over it, your no holds barred approach to the circuit will more than likely make up any diffs that may come due to the super stable clock? Do you know the jitter spec on the clock you're using? |

|

|

|

Post by svart on Dec 1, 2014 11:30:16 GMT -6

Well, I'm certainly not financially able to go that far in design like they are. I'm also shooting for a more narrow window of customer too. It's quite possible that they use a lot of the same design criteria on their product. The PCM4222 takes care of a number of aspects of the design for you. However, one big difference is that they are using a OCXO (oven controlled clock oscillator) based on the "Oven" LED on the front of the unit. The oven is a heater that keeps the oscillator at a specific temperature. I'm using a very lot jitter clock device, but it's not oven controlled. OCXO's are not cheap. Understood, i was curious to what you thought about the design is all. I'd bet what ever they did still has bean counters standing over it, your no holds barred approach to the circuit will more than likely make up any diffs that may come due to the super stable clock? Do you know the jitter spec on the clock you're using? Phase jitter of ~300fs Period jitter of ~2ps RMS Temp stability +/-7ppm Initial accuracy +/-1.5ppm Total stability +/-20ppm I can bet that they don't have bean counters standing over it. They had them go through it even before the design was prototyped. They wouldn't have let the designers even spend their time(time is money) on it without already knowing how much it would cost, roughly. Even then, it was probably just the marketing predictions on cost vs. sales. Not many companies have separate "bean counters" anymore as those bean counters cost the companies more money in salaries than they typically saved in cost cutting, especially for low sales items like that. |

|

|

|

Post by svart on Dec 2, 2014 9:26:19 GMT -6

So the ADC PCBs should be here today. I ordered the parts I need to populate a couple of them. Still working on the DAC layout.

Progress.

I'm also thinking that I'll end up ordering 20-30 batches of boards for the initial run, but only populating 10 batches at a time. That way I have cash flow paying for the parts on subsequent batches, until the capital is built up enough to sustain the whole builds. Adding the ongoing build costs up has definitely given me a new understanding of cash flow in companies.

|

|